The science of multiple certification

It always starts with safety. Uncovering a problem that needs to be solved.

Since the very start, we’ve worked to solve problems without obvious solutions. Since introducing the Skull Comp, our first helmet, we have always strived to create protection that matches how people ski. As the styles of skiing change, so too do people’s protection needs. It is this constant search for the right protection that is the reason we continue to innovate, the reason we continue to work to find new ways of keeping people protected from the kinds of impacts they are most likely to encounter if things go wrong.

In recent years, there have been tremendous leaps forward in technology that have resulted in more of the mountain becoming more accessible to more people. Greater numbers of skiers and snowboarders are heading away from the lift network and exploring other parts of the mountain. While many are using skins to get up, increasing numbers are mountaineering or climbing in order to ski or ride new lines. Inevitably, with only so much kit that can be physically carried, taking two different helmets: one for mountaineering and one for skiing, simply does not get done.

Just one helmet gets taken. And that exposes people to unnecessary risk for part of their time on the mountain. So, we set about creating a helmet that works just as well for the journey to the summit as it does on the way down.

The journey to the summit does not start at the base of the mountain: it starts at home. Therefore, we wanted the Calyx to be usable on a bike. We worked to make sure the helmet is comfortable to wear while cycling and carrying gear. Then, as the journey up the mountain progresses, the needs from a helmet change. So we wanted to make sure the helmet can keep you fully protected whilst mountaineering.

Passing cycling safety standards and ski standards together followed processes similar to those we follow when creating single-activity helmets, whether for any form of cycling or on snow. Both sets of standards expose the helmet to the same types of impact tests, and with relatively similar levels of force. It was natural to fine-tune the process in order to ensure a single helmet could successfully pass both tests.

Ensuring this helmet could withstand the very different kinds of impact that a mountaineering helmet is exposed to—and tested for—presented us with new and different kinds of obstacles to overcome.

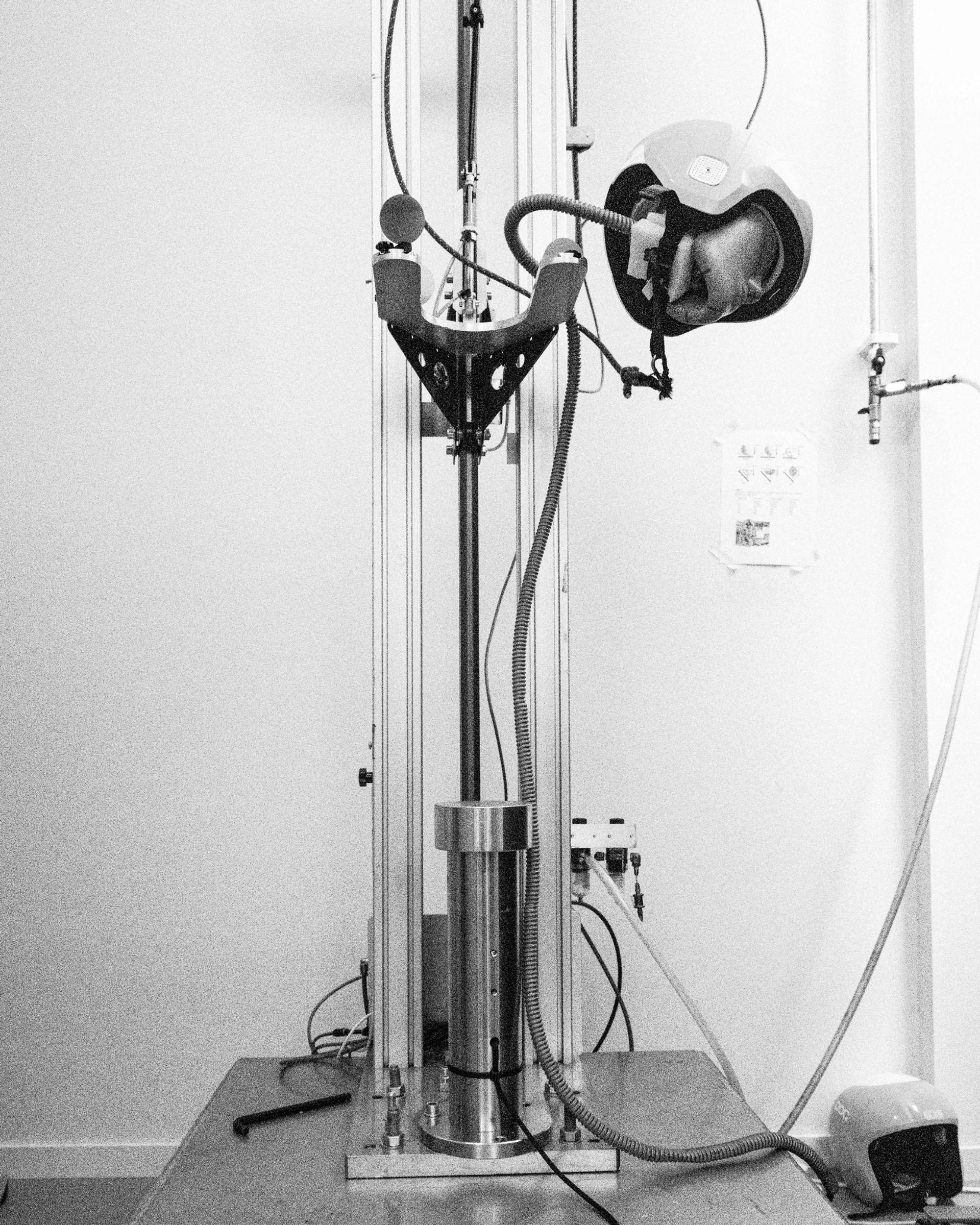

Here, the aim is to protect from falling rocks, rather than from when the wearer themself falls. These are very different impact forces, often in different places on the head. We began by conducting extensive modelling and analysis to see just how different the helmet would need to be.

It is common for mountaineering helmets to feature a much harder outer shell than would be effective—or safe—for a cycle or ski helmet, as it would prevent the inner EPS liner from absorbing the impact shock effectively.

A central problem to overcome, therefore, was how to create a helmet with a shell stable enough to withstand the impact forces of falling rocks and other mountaineering-related impacts, yet not so hard that it would negatively affect the performance of the EPS liner in a ski or cycling accident.

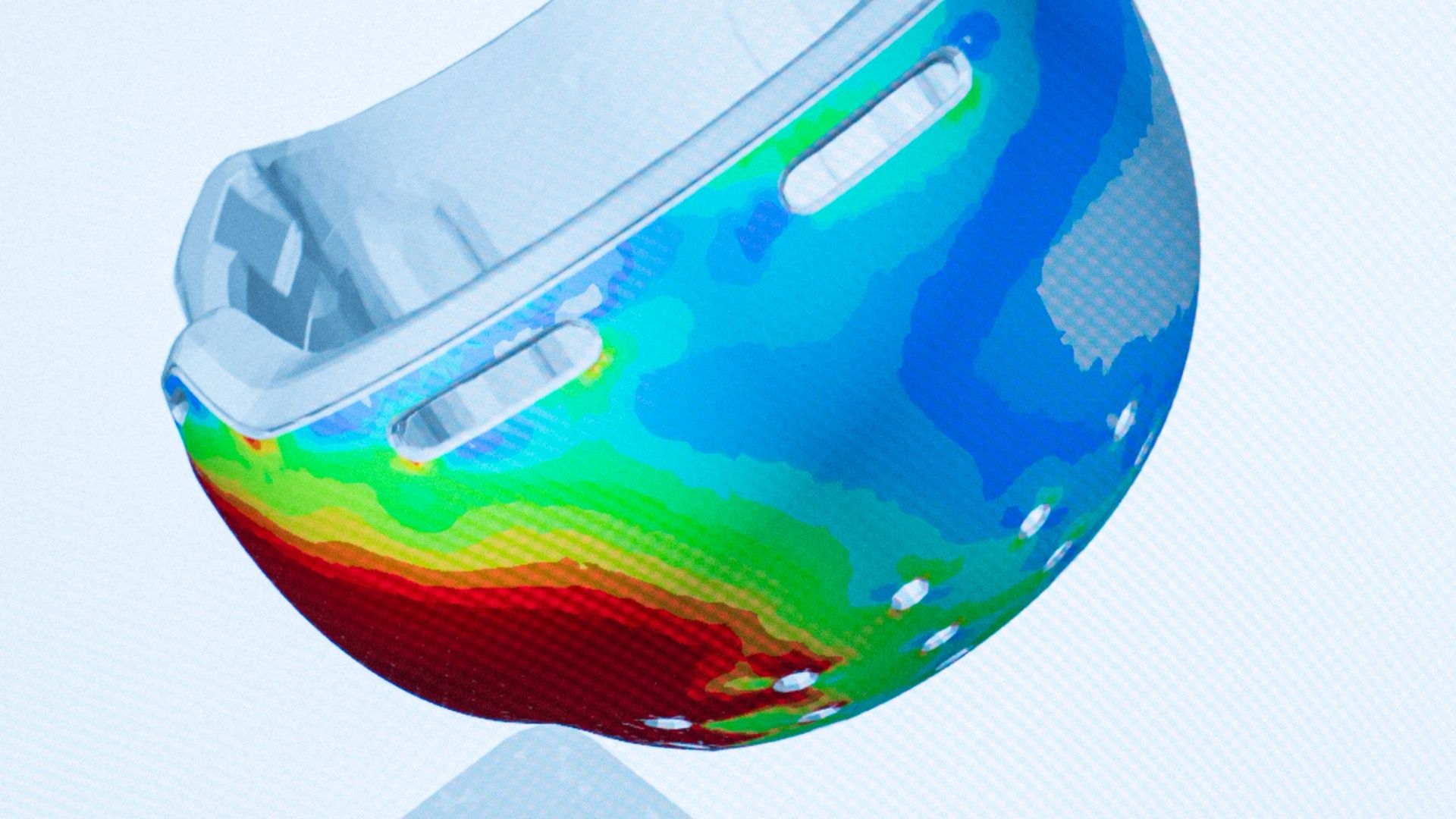

This presented an opportunity for our in-house FEM engineer Ebba Larsson Regnström to test and analyse different combinations of helmet liner and shell materials, densities and thicknesses, making it possible for our designers to iterate more quickly and gain better insight into a helmet’s protective properties before any physical tests took place.

The results of this testing process led us to a solution with a dual-density EPS liner so that impact absorption in different parts of the helmet is fully optimised.

Repeating this analysis after prototyping further helped us choose the right development path to create a helmet that could work in numerous very different situations.

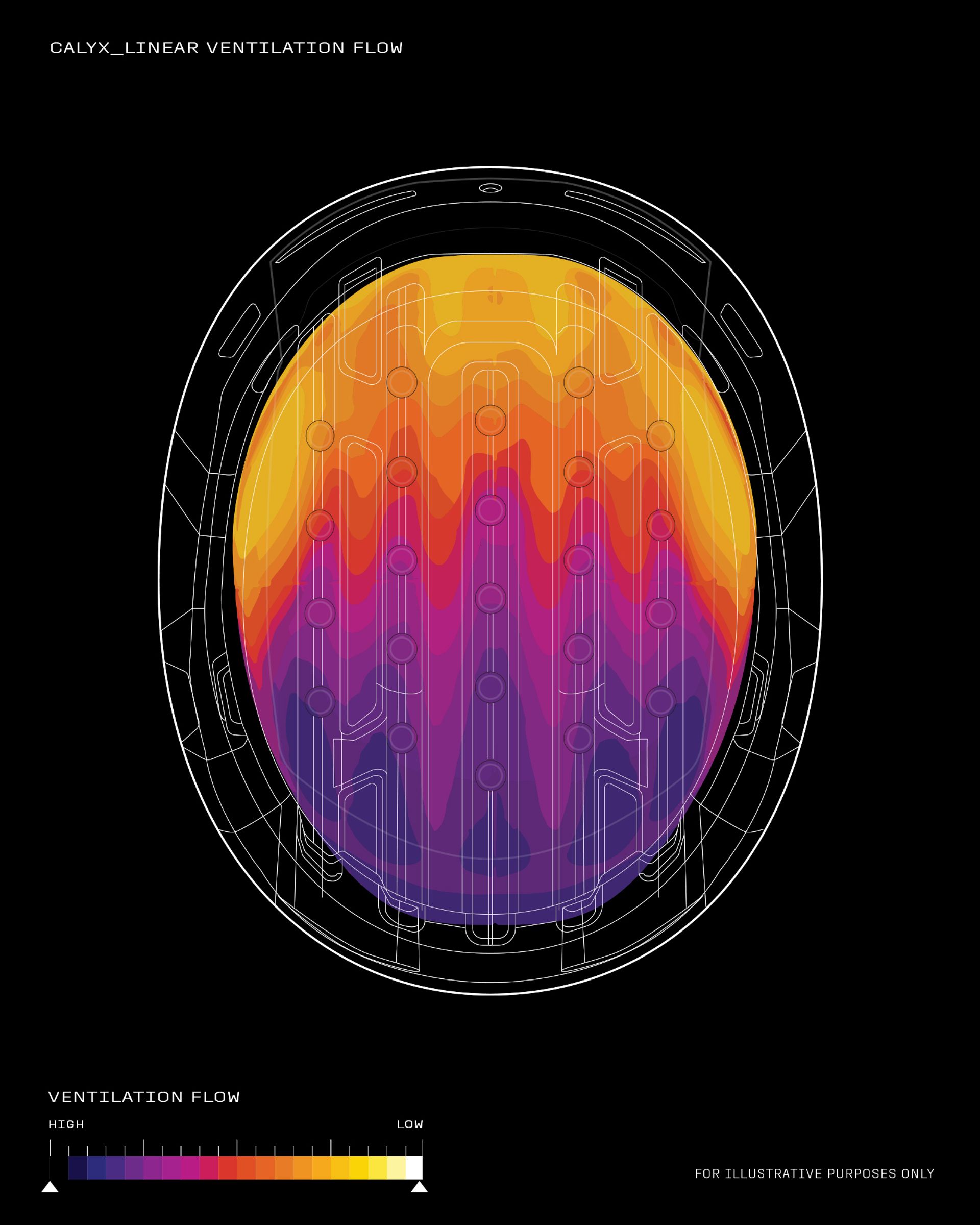

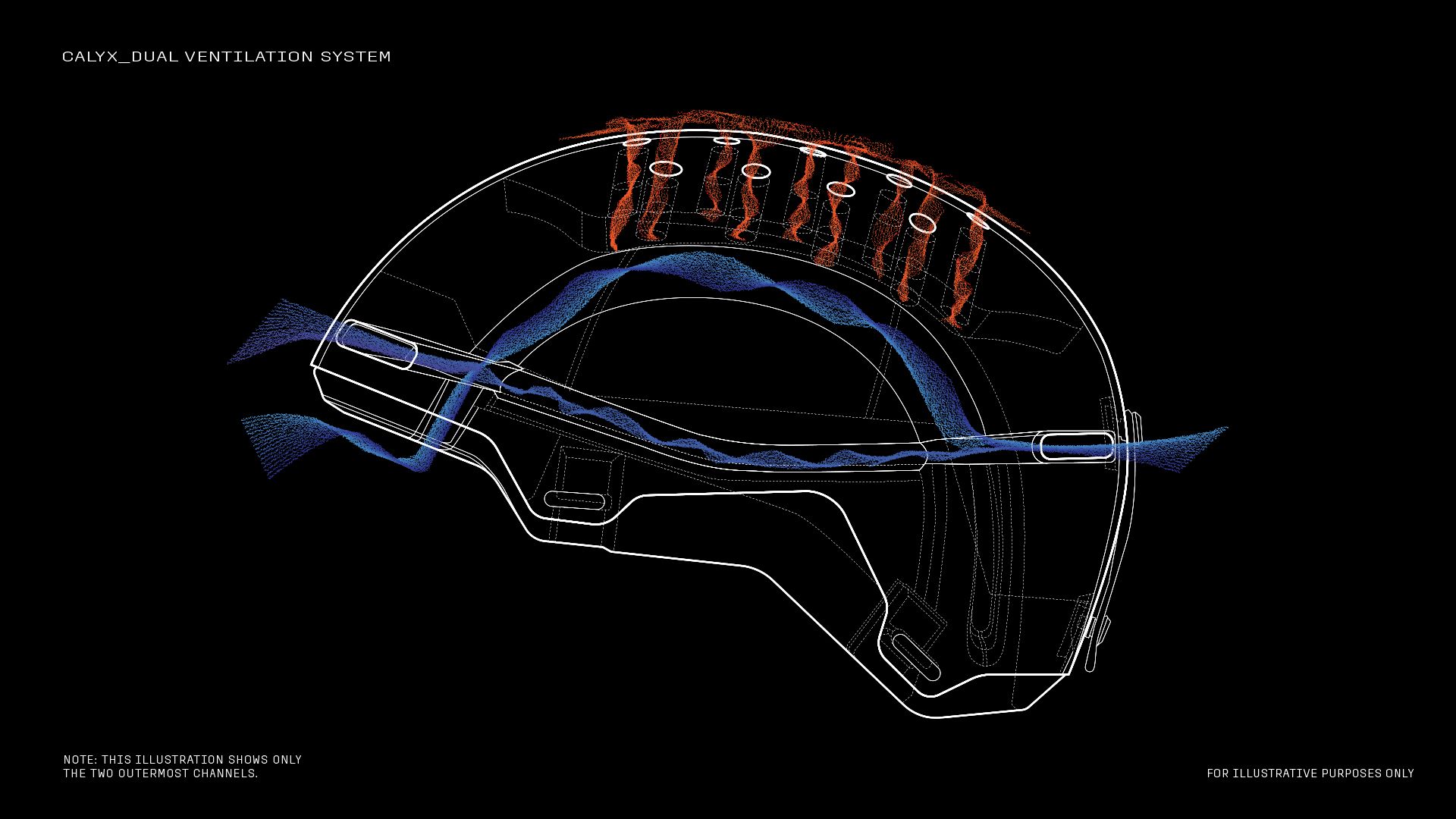

But just because the helmet can protect in different situations does not mean it can be used comfortably in all situations. Ventilation plays a vital part in comfort in any situation, and the user requirements for how a helmet is ventilated differ greatly based on the specific activity in which the helmet will be used. This is why we created the twin ventilation system, which features both linear channels and chimney-like vents at the top of the helmet.

Note: The illustration shows only th

The top vents come to the fore when climbing and mountaineering, as they allow heat to escape as it rises, without the need for airflow through the helmet to create a cooling effect. A three-step adjustment system here gives each user complete control over how much ventilation they use based on their own personal requirements and the prevalent weather conditions.

The linear channels, inspired by our road and mountain bike helmets, allow air to flow freely through and over the head, providing a comforting cooling effect whether cycling or skiing. The addition of fabric over the front and rear intake and outlet vents helps to take the chill off the air as it enters the helmet, giving improved comfort while skiing.

This combination of ventilation solutions came together as a result of modelling and real-world testing, including hill-climbing in some of our cycling helmets, to discover exactly how the ventilation needed to perform.

The result of overcoming these challenges, both for how the helmet can protect and how it feels when worn, is the Calyx: the multi-functional helmet based on modular principles that makes it possible to get from your door to the top of the mountain and back again.

Or if you’d rather just wear it in the city? Well, it works there, too.

Photos by: Robin O'Neill & POC Sports

Related articles

Considered Performance

In developing the Elicit Ti, we sought to find a way to deliver all the benefits needed to stay at the cutting edge of performance cycling while being considerate of the resources we use.

Ready for anything in Riksgränsen

In skiing, conditions are constantly changing. Temperatures rise and fall, snow melts and refreezes, the wind blows, and the light fades. So there's no better place to be tested by extreme conditions than Riksgränsen, a mountainous wilderness in the heart of the Swedish Arctic. It's where dark winter days contrast with bright summer nights, and the snow lasts from September through June.

VPD: The material to protect your mobility

We test our body armour to the European EN1621 standard. Originally developed for motorcycle body armour, it has become the norm used across the bike and snowsports industries, given the similar types of impacts and forces users may experience. A key difference, however, is the range of body movement the wearer needs while performing. Here, we work to ensure that freedom of movement is always as high as possible. Protectors are graded to Level 1 or Level 2 standard, where Level 2 offers the most impact protection.