Helmets

2022 - One of our latest helmets, Myelin, uses recycled materials wherever possible. The helmet has a glue-free construction to make it easier to separate into its constituent parts at the end of its life. Engineered to be deconstructed, the Myelin can easily be broken down so all different materials used can be separated and recycled where possible.

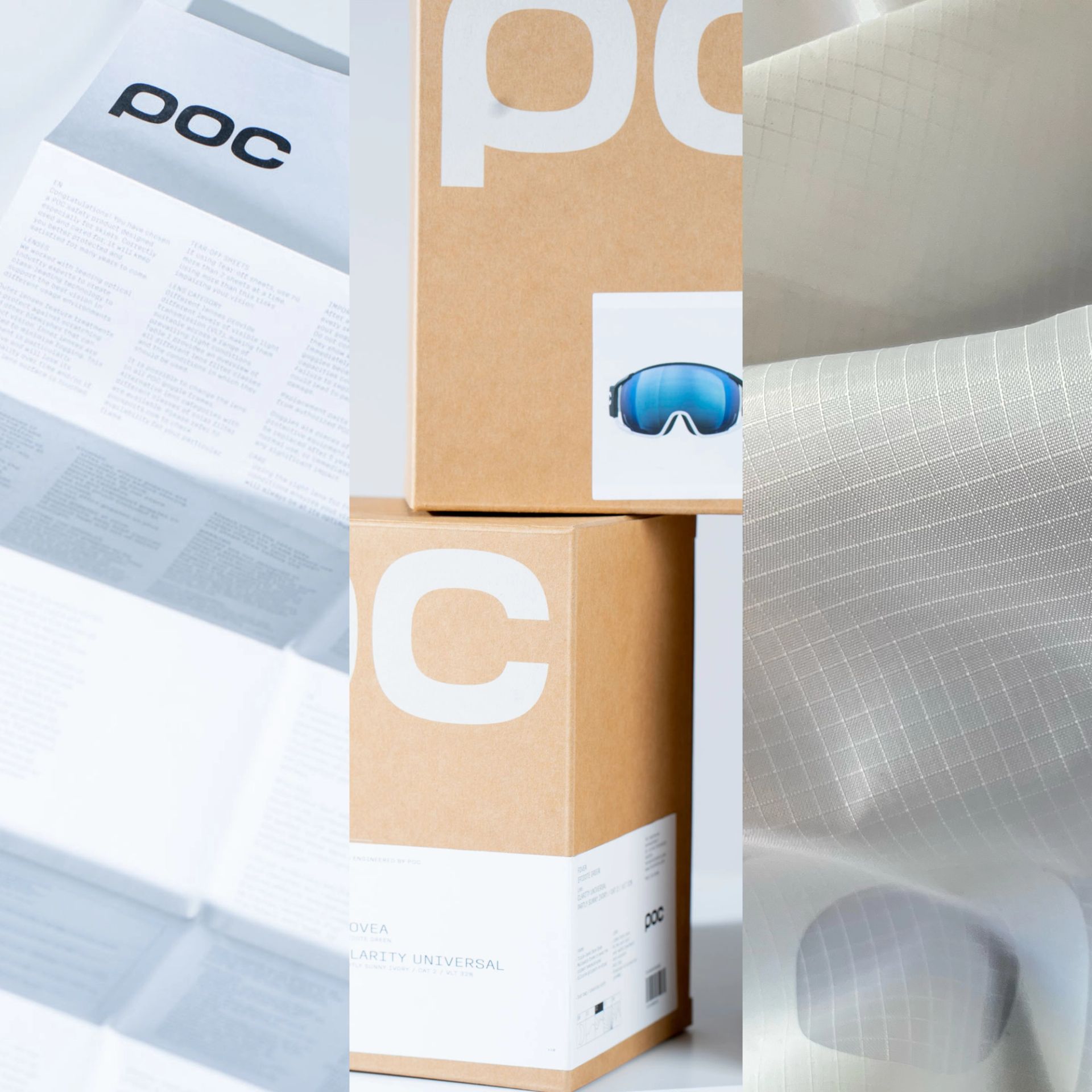

Eyewear

2019 - Our performance eyewear uses snap hinges and replaceable lenses to lengthen the lifetime of the products and make them more versatile.

From 2022 bio-based materials feature in almost all of our eyewear styles.

Apparel

2020 - For our cycling collection, we used leftover fabrics from earlier productions as the starting point for creating a limited-edition upcycled apparel range.

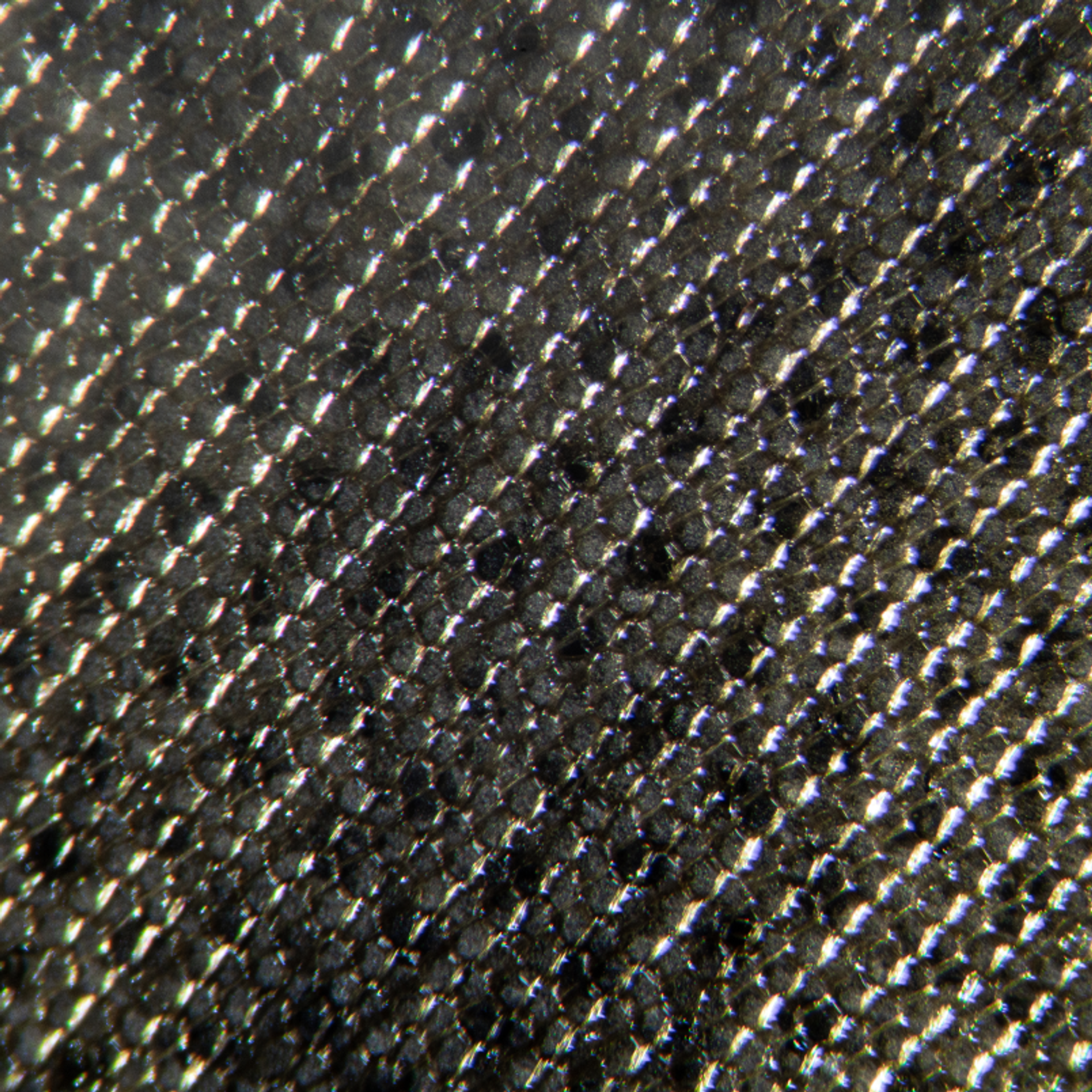

Since 2021, our biggest-volume apparel styles for cycling use GRS-certified recycled polyester.

Protective Backpacks

2020 - Our range of protective backpacks now feature PFC-free DWR and recycled fabrics.